Description

Product Overview:

Spindle motor has the advantages of fast speed. small volume. lightweight. low material consumption. low noise. low vibration.It is widely used in wood. aluminum. metal. stone. metal. plastic and other materials carving processing. widely used in many industries. can greatly improve the processing quality and accuracy.

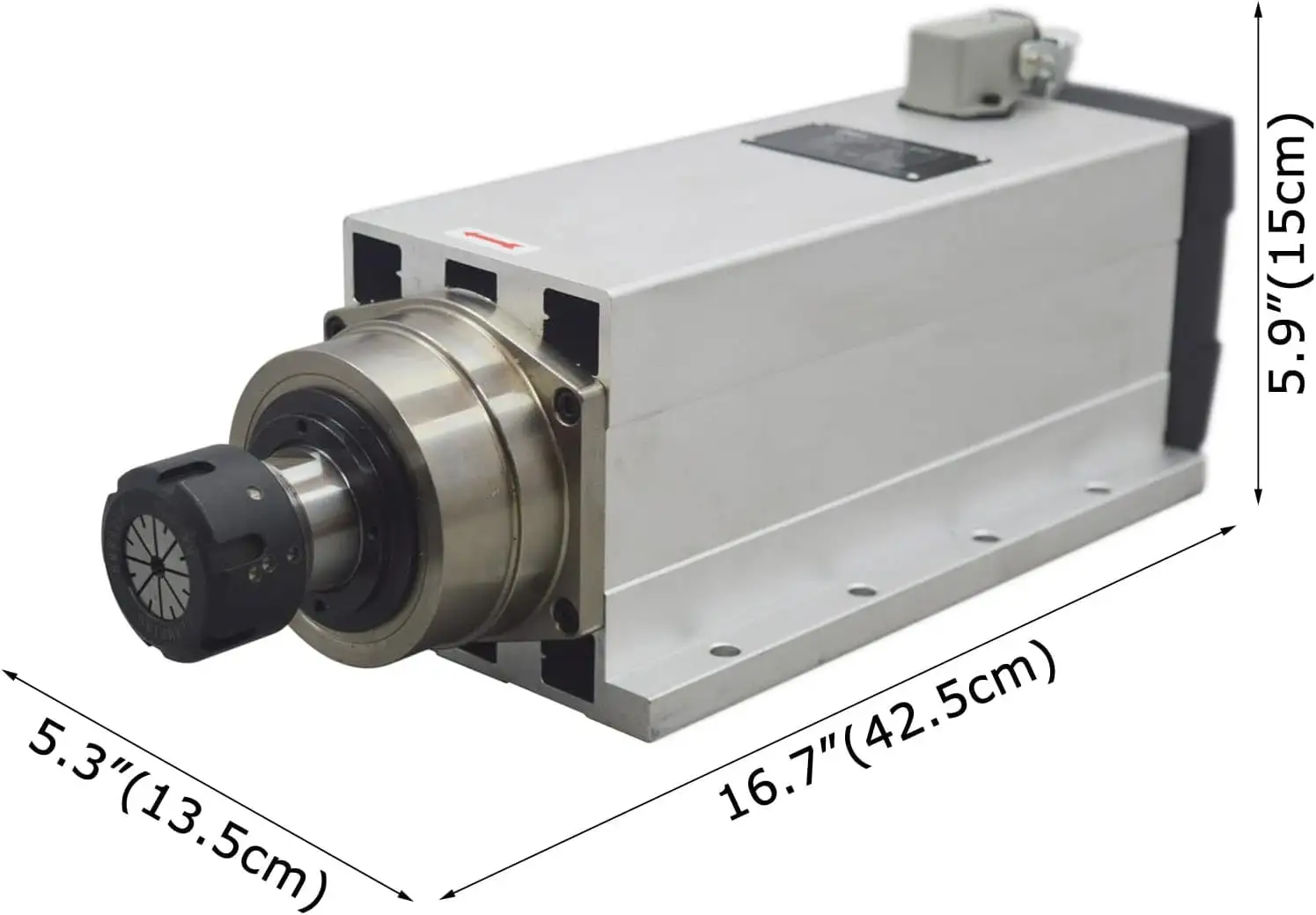

Product Parameters:

1. Voltage: 220V

2. Power: 7.5KW(10HP)

3. Current: 30.09A

4. Operating Frequency: 300Hz

5. Collet Nut: ER32

6. Clamping Range: 0.118-0.787(3mm-20mm)[Standard with 6mm collet. if you need other sizes please contact us]

7. Clamping Diameter of Collet: 0.236(6mm)

8. Motor Speed: 18000rpm

9. Cone Hole Beat: 2UM

10. Cooling Mode: Fan Cooling

11. Lubrication Mode: Grease Lubrication

12. Fuselage Material: Pure Aluminium

13. Packing Size: 20.1*9.1*8.7(51cm*23cm*22cm)

14. Net Weight/Gross Weight: 37.5LB(17kg)/39.0LB(17.7kg)

NOTE: Spindle motor must be equipped with frequency converter.Set up frequency converter correctly according to machine requirement. The item is not included frequency converter.

Features:

1. Through the inverter to adjust the output voltage and frequency can be achieved 0-18000 stepless.

2. High precision bearing and pure copper coil. high machining accuracy. long service life.

3. Pure aluminum body. anti-oxidation and anti-corrosion. lighter weight.

4. Adopt precision steel ball holder to ensure spindle rotation accuracy in high speed grinding.

5. Lubricating grease resistant to high temperature of 200??. low noise.

Matters Need Attention:

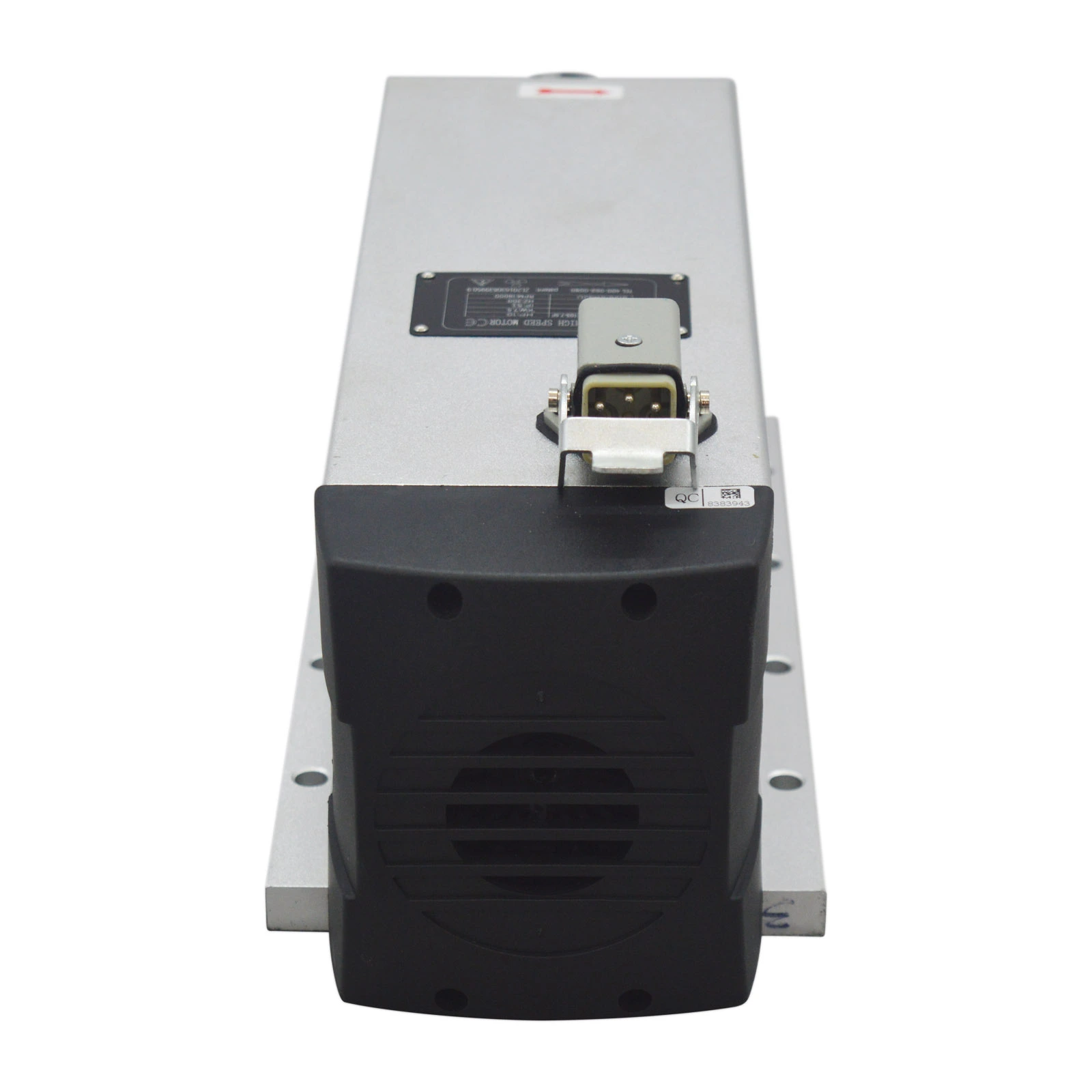

1. Must match the drive spindle chosen correctly according to the electric spindle nameplate good debugging power. voltage and frequency.

2. Set the frequency converter should be set command channel. and then set the display channel. and finally set the parameters. When setting parameters. be sure that the reference frequency. the frequency of the three highest rated frequency and consistency.

3. The spindle is generally clockwise in the wrong direction. the drive can change settings or swap any two rotating wire the inverter output UVW terminal on.

4. In general. water-cooled spindle surface temperature and ambient temperature greater than 20 degrees. the heat can be considered a spindle; when air-cooled spindle surface temperature greater than ambient temperature of 30 degrees. can be identified as the main heat seriously. immediately shut down cooling. a check.

Item Included: 056291

Spindle Motor Main Shaft Motor Router Engraving Milling Machine 220V with Flange for Woodworking ER32

-

Widely used in wood. aluminum. metal. stone. metal. plastic and other materials carving processing. widely used in many industries. can greatly improve the processing quality and accuracy.

-

With speed of 18000rpm. the efficiency and service life of the CNC router grinding spindle motor can be significantly improved. And The nut using manganese steel is hardened with high precision. not easy to break the knife.

-

Using fan cooling mode. compared with water cooling is more simple and convenient. can discharge a lot of heat generated by the work quickly. extend the service life greatly. This spindle motor adopts dynamic balance technology which can effectively reduce the noise in the process of use.

-

Adopt precision steel ball holder to ensure spindle rotation accuracy in high speed grinding. High Precision ER32 nut. standard with 6mm collet. another clamping range of 3-20mmm.

-

Covenient and trouble-free. no water pipe/sink and pumb. just connect to the inverter and use it.

Specifications

| Manufacturer Part Number | 056291 |

| Brand | ?EQCOTWEA |

Reviews

There are no reviews yet.