Description

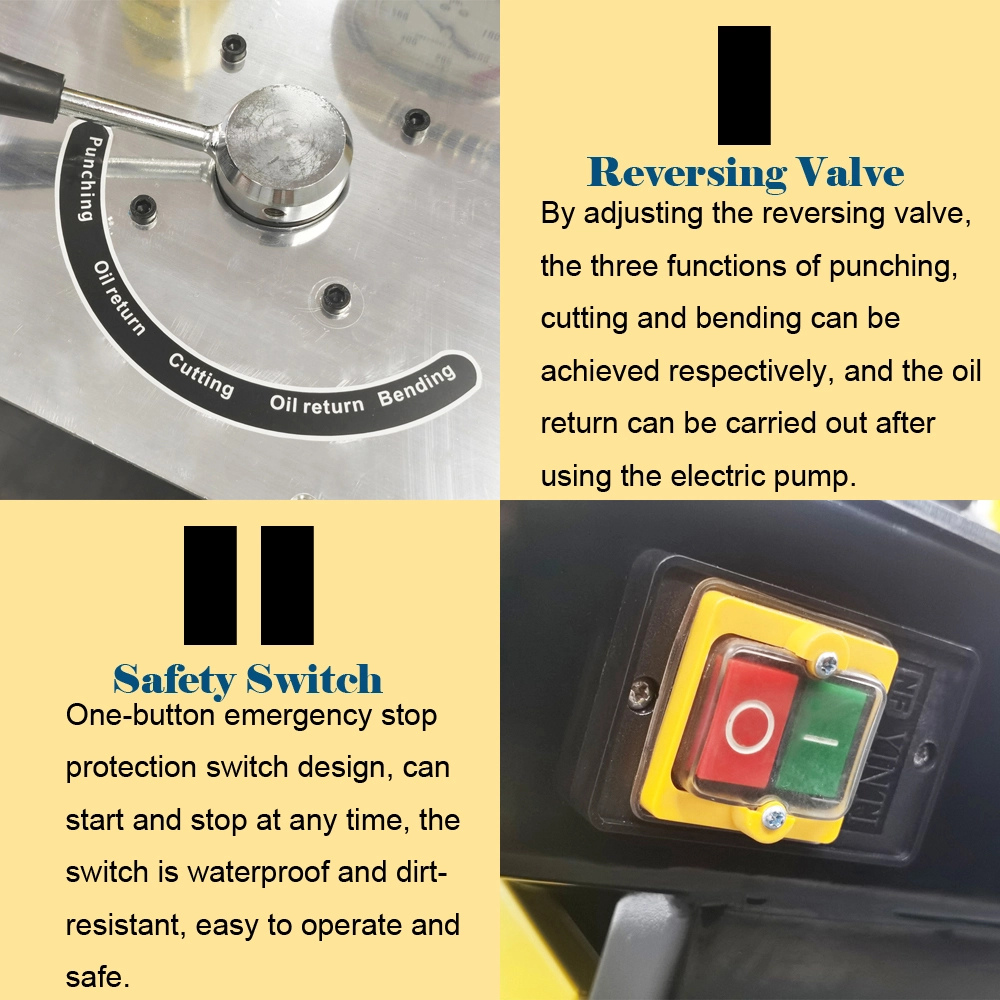

Busbar processing machine has shearing. punching. bending three processing units. the main function for processing different specifications of copper. aluminum bus. just use the corresponding processing unit. can be convenient. fast to copper. aluminum row shear. punching. bending and other different processing. It is an indispensable equipment for sheet metal processing. which can greatly improve production efficiency and is widely used in all walks of life.

Parameter:

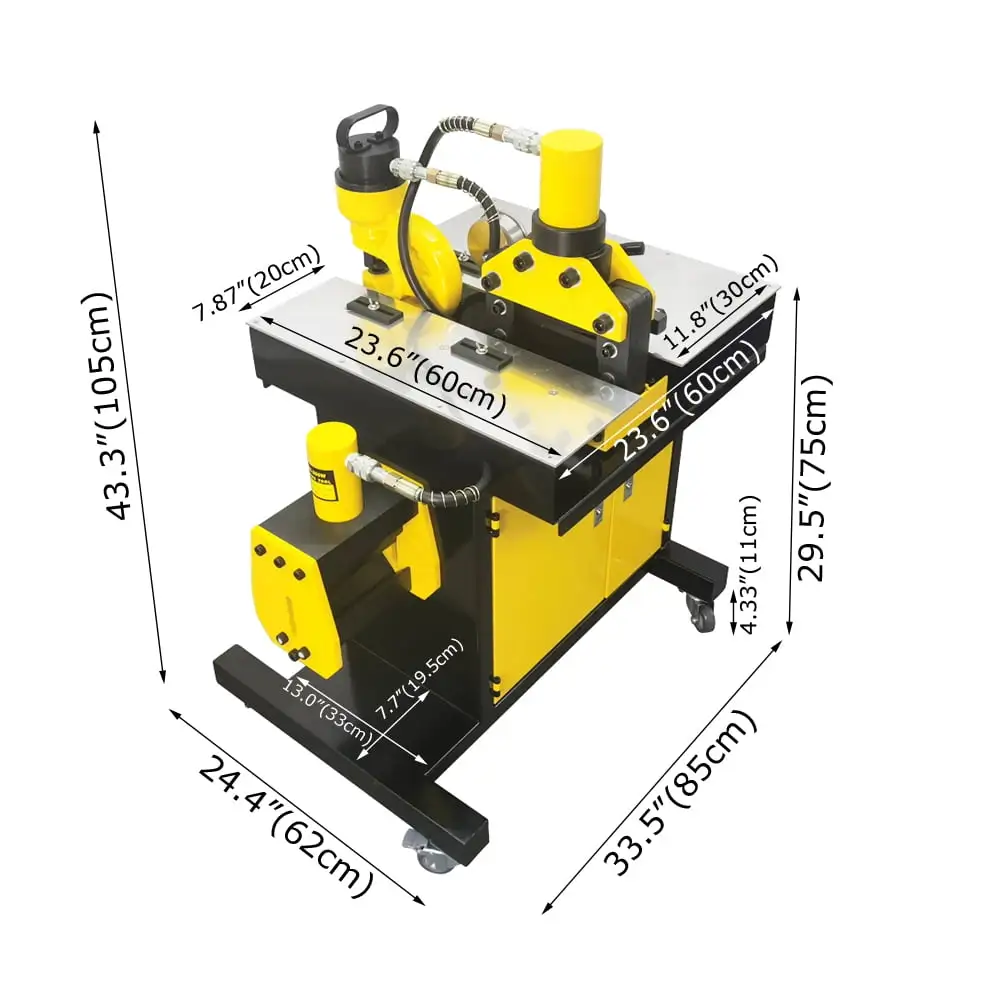

Model: HHM-150H

Voltage: AC110V

Power: 1.2HP(900W)

Output cutting force: 20ton

Output punching force: 31ton

Output bending force: 16ton

Cutting max(Width*Thickness): 5.90*0.39(150mm*10mm)

Punching max(Thickness): 0.39(10mm)

Bending max(Width*Thickness): 7.87*0.47(200mm*12mm)

Throat depth of punching: 2.75(70mm)

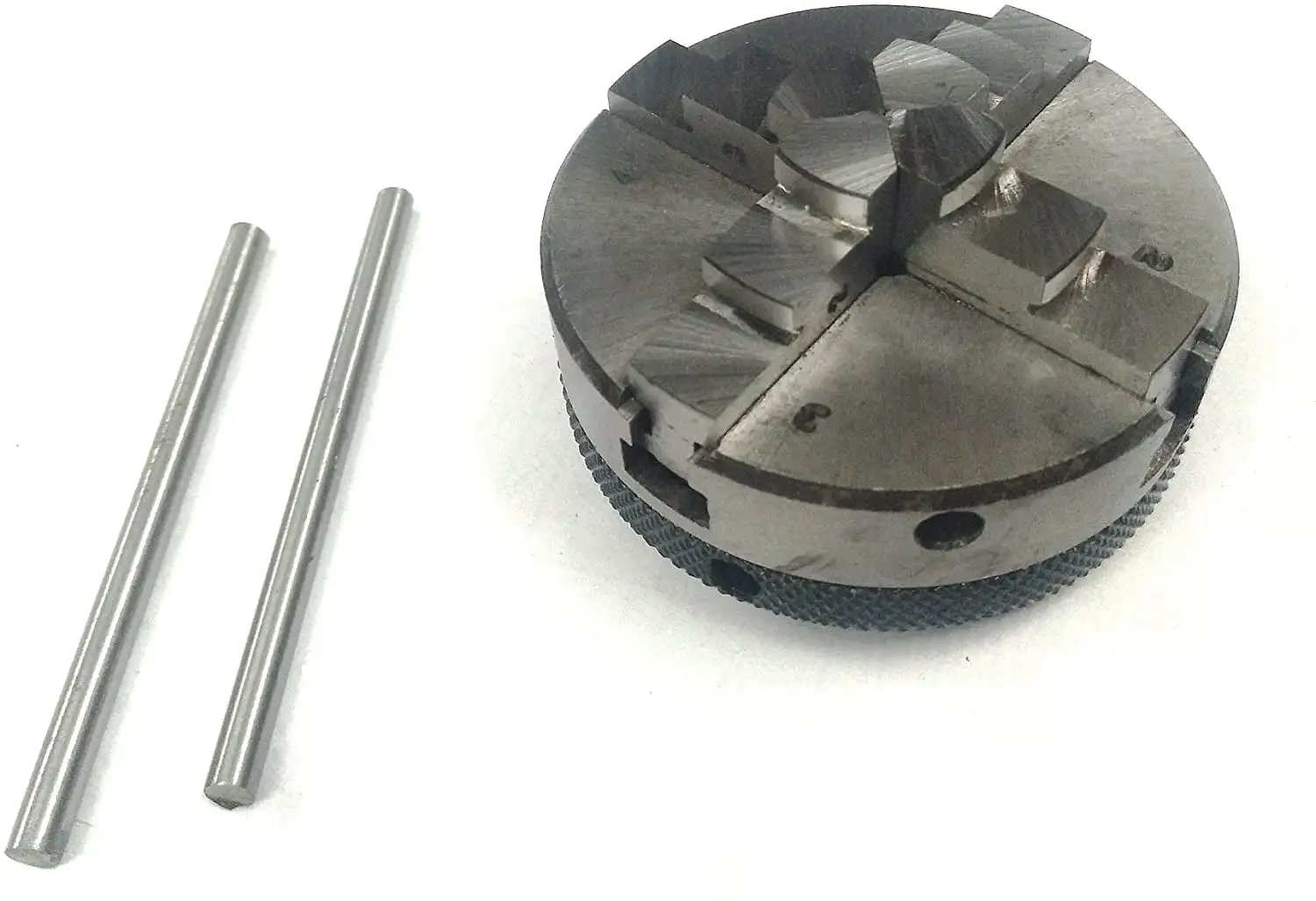

Punching dies: 3/8/5/8/1/2/3/4

Hydraulic pump pressure max: 700bar(10152psi)

Tank capacity of hydraulic pump: 2.11gal(8L)

Flow rate of hydraulic pump: 0.7L/min-5L/min

Package size: 48.4*28.0*37.0(94cm*71cm*123cm)

Net weight/Gross weight: 335LB(152kg)/419LB(190kg)

Items Included: 056276

Busbar Processor *1

Punching Dies *6(Three sets)

Dowel *1

Wrench *1

English Manual *1

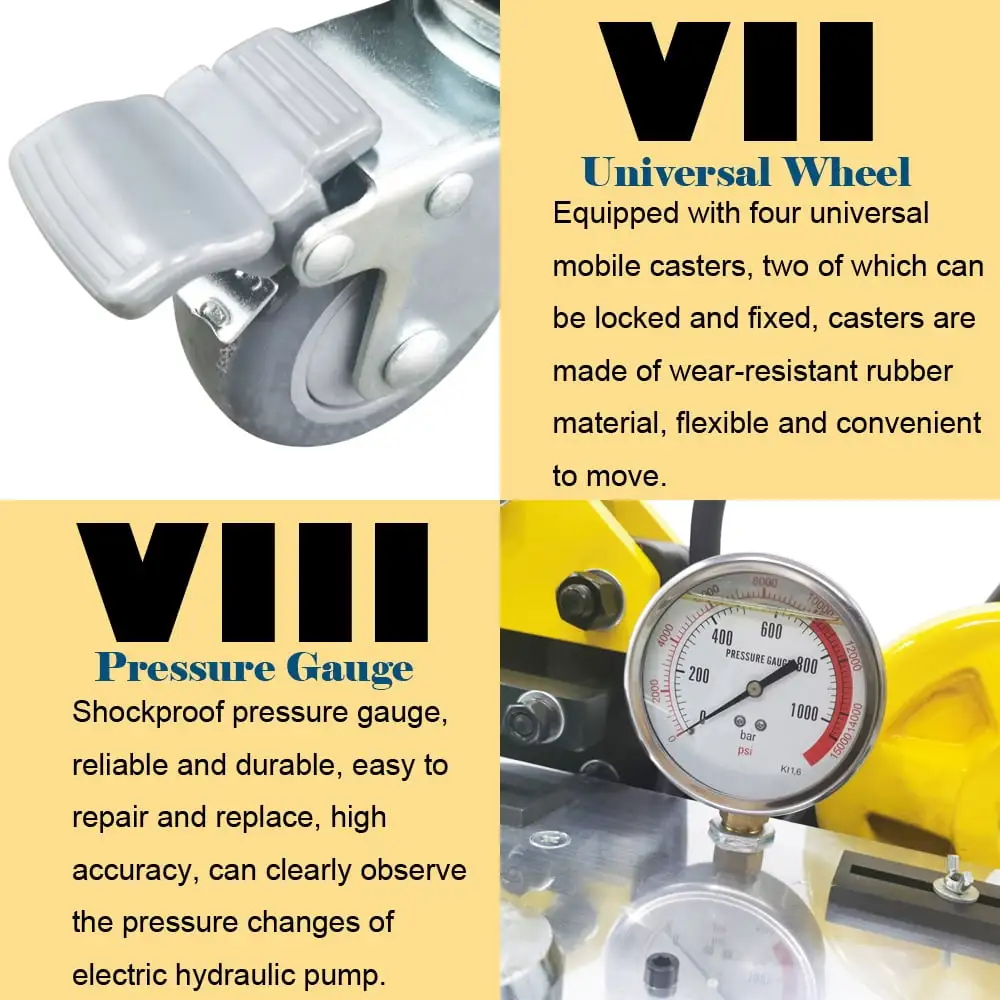

- The working table is polished by mirror. grinding and chrome plating. rust resistance. abrasion resistance and collision resistance.

- No burr after punching; The cutting surface is smooth without indentation and burr. one bending molding. high precision.

- Electric 700bar hydraulic system. can provide enough pressure; Low noise.

- The 1000kg/cm2 oil-filled hydraulic gauge allows the operator to perform machining operations according to the pressure index. avoiding overload damage to equipment.

- Pure copper core motor to ensure long-term stable operation of equipment; High quality. high sealing rubber pipeline to ensure that the loop will not leak hydraulic oil.

Specifications

| Manufacturer Part Number | 056276 |

| Brand | intsupermai |

Reviews

There are no reviews yet.