Description

1. When using. it should be noted that there should be no foreign matter such as stones and ironblocks in the raw materials. After the pellet machine has been working continuously for morethan ten shifts. the pressure roller oil hole. the universal joint oil hole. and the linkage shaft oilhole need to be filled with high-temperature lubricating grease to make the pressure roller Goodworking performance and extended bearing life.

2. During granulation. it is strictly forbidden for the pressure roller to contact with the templateto run idly. and the continuous feeding can not be interrupted.At the same time. the pressureroller shaft nut is locked to avoid loosening and damaging the spindle keyway.

3. When granulating. there is no granulation. no discharge. the template should be removed. andafter opening one by one. some fiber feed can be added appropriately to restart the granulation4.Always check the tightness of the screws in each part of the machine. If there is oil leakage inthe gearbox.replace the oil seals in time. and check whether the bearings in the machine headare short of oil.

4. When the pellet machine is working. do not reach into the feeding port with your hands. Ifnecessary. use wooden sticks to help feed the pellets.

5. Before turning on the machine. it is necessary to add less material before turning on the machine. When shutting down. leave a small amount of feed in the machine to prevent the pressroller of the machine from contacting the template from idling.

6. If the machine is stuck in operation. stop it immediately. press the pressure roller until thebolt is flat. and then restart the machine.

7. Each time the work is completed. the adjusting pressure roller bolts must be loosened.

Features??

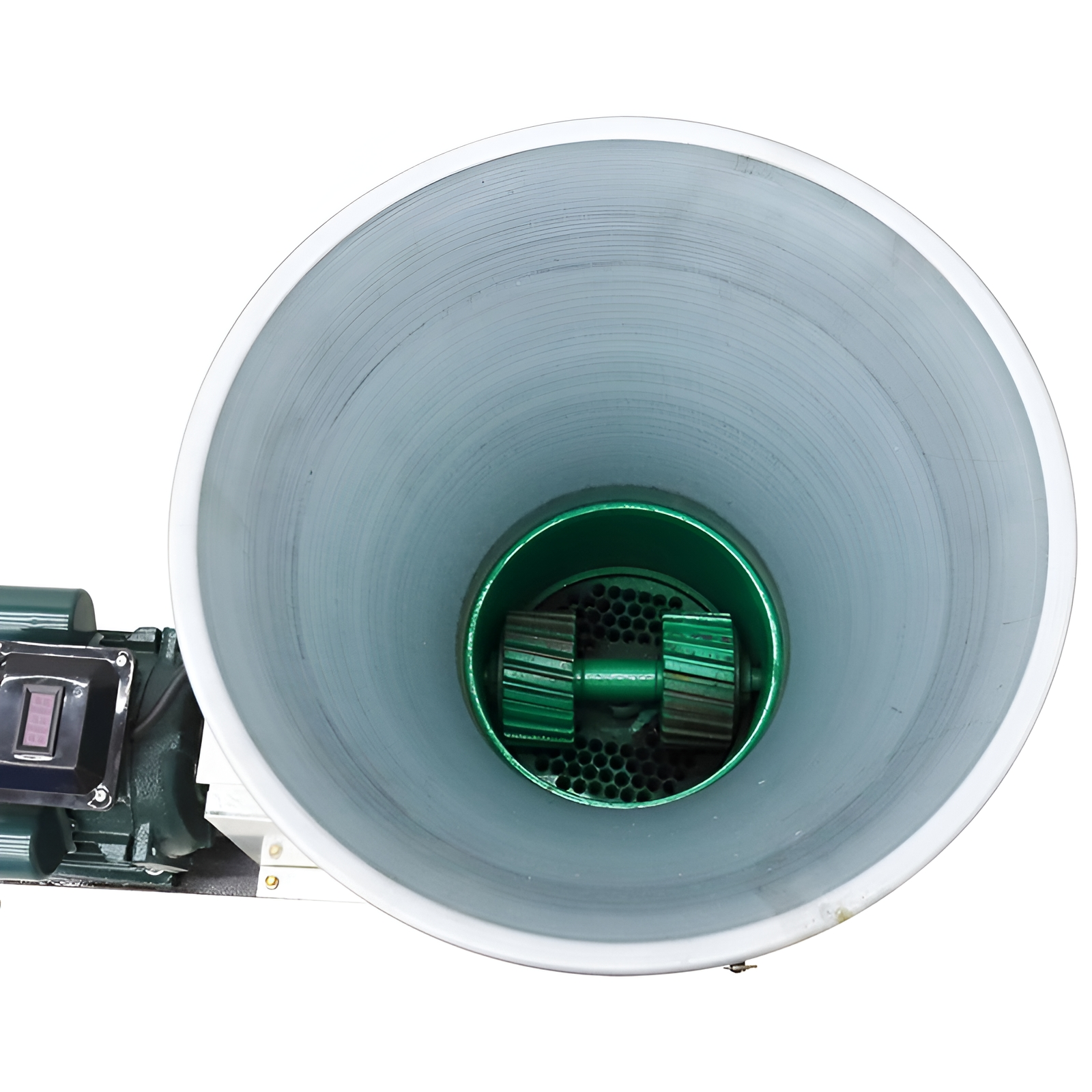

1. This machine can quickly make chicken feed. The output is up to 150KG per hour. Grinding disc hole diameter is 4MM.

2. The feed processed by the machine is smooth and has moderate hardness. The microorganism and parasite can be killed during the process by extrusion.

3. The temperature-change during the process is slight so the nutrition can be contained very well.

4. Voltage: 220V

Operation:

1: Add oil into gearbox before start.

2:Double-check the belt and the screws before operation.

3:Clean up the rest after use to prevent damage to the machine.

Item Included: 239252

INTSUPERMAI Farm Animal Feed Pellet Mill Machine 4MM Chicken Duck Poultry Raise 220V 150KG/H

- The machine is mainly suitable for the processing of rabbits.fish. ducks.chickens.shrimps.pigs.cattle.sheep and industrial pellets.Widely used in industrial.plastic pellets.organic fertilizer particles.wood pellets.etc

- This machine can quickly make chicken feed.grinding disc hole diameter is 4MM(We also have different size of disc.such as 2mm.3mm.4mm.5mm.6mm.8mm.12mm).The rollers and grinding discs of this product are hardened at high temperature and are very wear-resistant and durable.

- The machine is made of steel with paint sprayed on the surface for long service life. Big size inlet and outlet for easy input and easy discharge. Wheels at the bottom for easy transport.

- The enlarged feeding port design makes feeding more convenient and high working efficiency. The baffle design of the discharge port can effectively prevent the feed from scattering. The machine is equipped with wheels for easy movement.

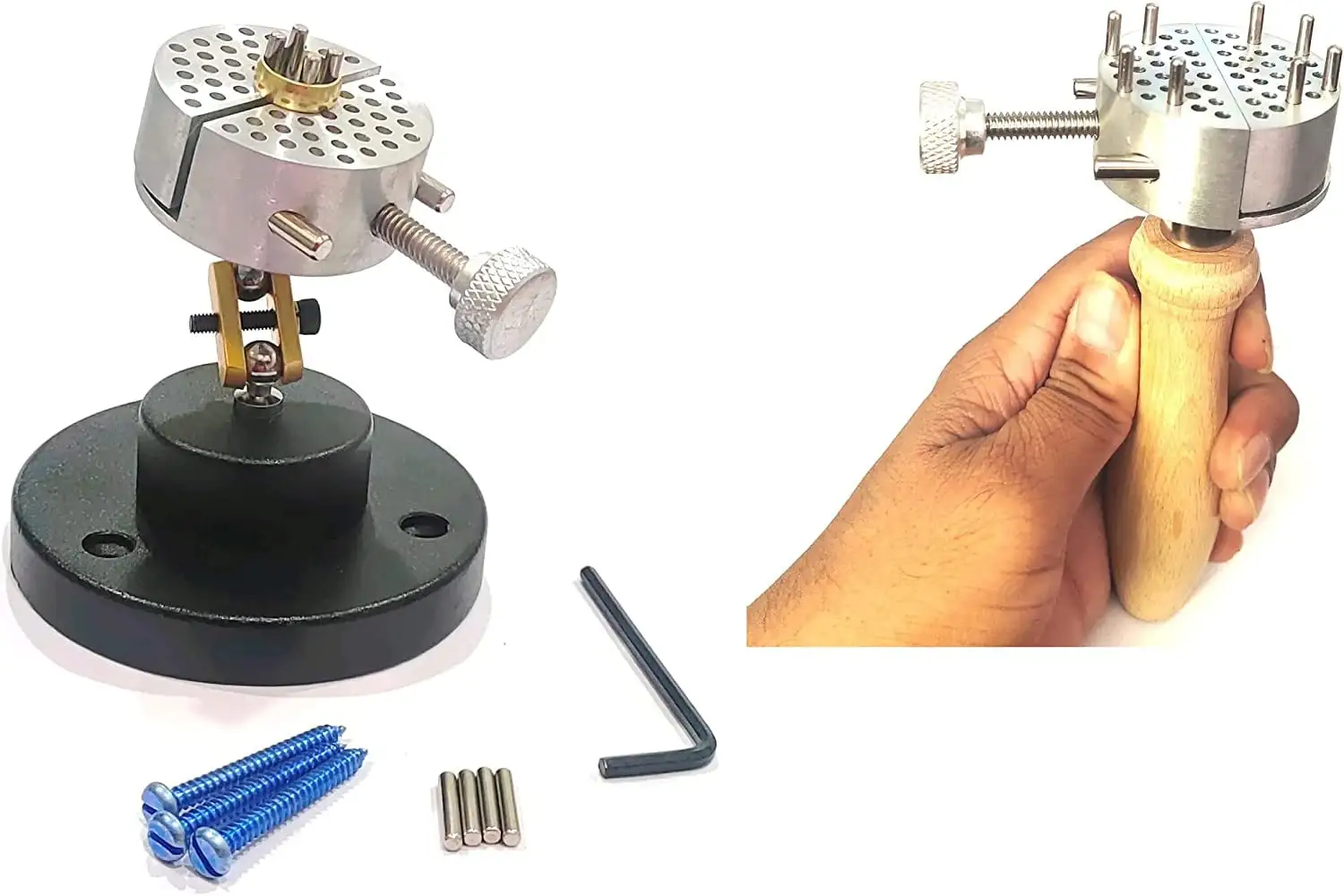

- Adjust the distance between the pressure shaft and the grinding disc. and be sure to keep the balance adjustment of the nuts on both sides when making particles. so as not to damage the pressure roller and the grinding disc.

Specifications

| Manufacturer Part Number | 239252 |

| Brand | intsupermai |

Reviews

There are no reviews yet.